Tim's RV14 Build - Wing Ribs / Rear Spar / Top Skins

/ Leading Edge

Added 2/11/2013This update includes the following sections:

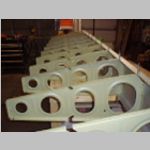

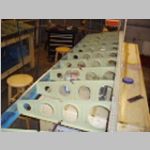

- Wing Ribs

- Rear Spar

- Top Wing Skins

- Outboard Leading Edge

As we got moving on the kit, I was also involved in a windows 7 "downgrade" from windows XP on my computers at home, so I found myself not having much time to actually use the computers for what they were intended. I had to purchase many software items to run on Windows 7 too. Being a geek at heart, this stuff took some priority to doing my updates and writing. When push comes to shove, something had to go, and it wasn't going to be working on the kit or getting the network all working good again.

The RV-14 wing is very very similar in process to building the RV-10 wing, and I still keep finding myself looking at my old RV-10 write-ups to keep perspective on what is going on. I've found a few plans errors along the way, some of which caused me a little wasted cash and time. One in particular I was sadly led astray by comments of a non-14-builder on one of the forums, that made an off-the-cuff remark that made me question things that I thought I knew very well. Then when I came across the plans error, it really got me questioning myself. Sadly, rather than trusting my instincts, I drilled the holes and built the part to look like the plans...which resulted in me buying a couple of wing ribs and parts to remake the whole thing. This just goes to drive home a lesson for you readers. "Don't trust everything you read on the internet." Of course, you already know that, but I'm saying that you shouldn't even trust what you read here on my site. The plans aren't perfect, and neither am I, so if you're building, always read the plans and ask questions until you know the answer for sure. I am finding that whereas the RV-10 plans gave a little more explanation as to why you do or don't do a step, such as dimple various holes but not others, the RV-14 plans gives a little less "foresight" comments. They tell you for instance, not to dimple the tops of the wing ribs while you're dimpling the bottom. But, in reality, they are just trying to keep you from dimpling the innermost ribs, where the wing-walk doubler will be. Knowing some of this ahead of time could help you move ahead a little quicker, and having built before, it was easy to see what was going to happen...but if you're a first-time builder, you're going to have to spend time looking ahead at the plans to get a feel for what the end result is on various steps.

update 2/12/2013: Van's just emailed info today regarding a boat load of plans revisions. There were quite a few items on the list.